BCS is designed to maintain sweet gas pressure at the inlet of existing BCS-1 of Alan field under formation energy depletion conditions in order to ensure processing and further transportation of the gas.

Raw sweet gas is fed from wells to BCS inlet in the amount of

BCS technical data:

|

Parameter description |

Value |

|

Dimensions: |

|

|

Total area, m2 |

93.6 |

|

Structural volume, m3 |

540.0 |

|

Columns spacing, m |

3.7 |

|

Number of entrances (gates with doors), pcs. |

1 |

|

Hand chain hoist, pcs. |

1 |

|

Area of blast-relief structures |

|

|

Room category as per RD 12.13130 |

А |

|

Fire resistance rating |

IV |

|

Structural fire hazard class |

С0 |

|

Functional fire hazard class |

F5.1 |

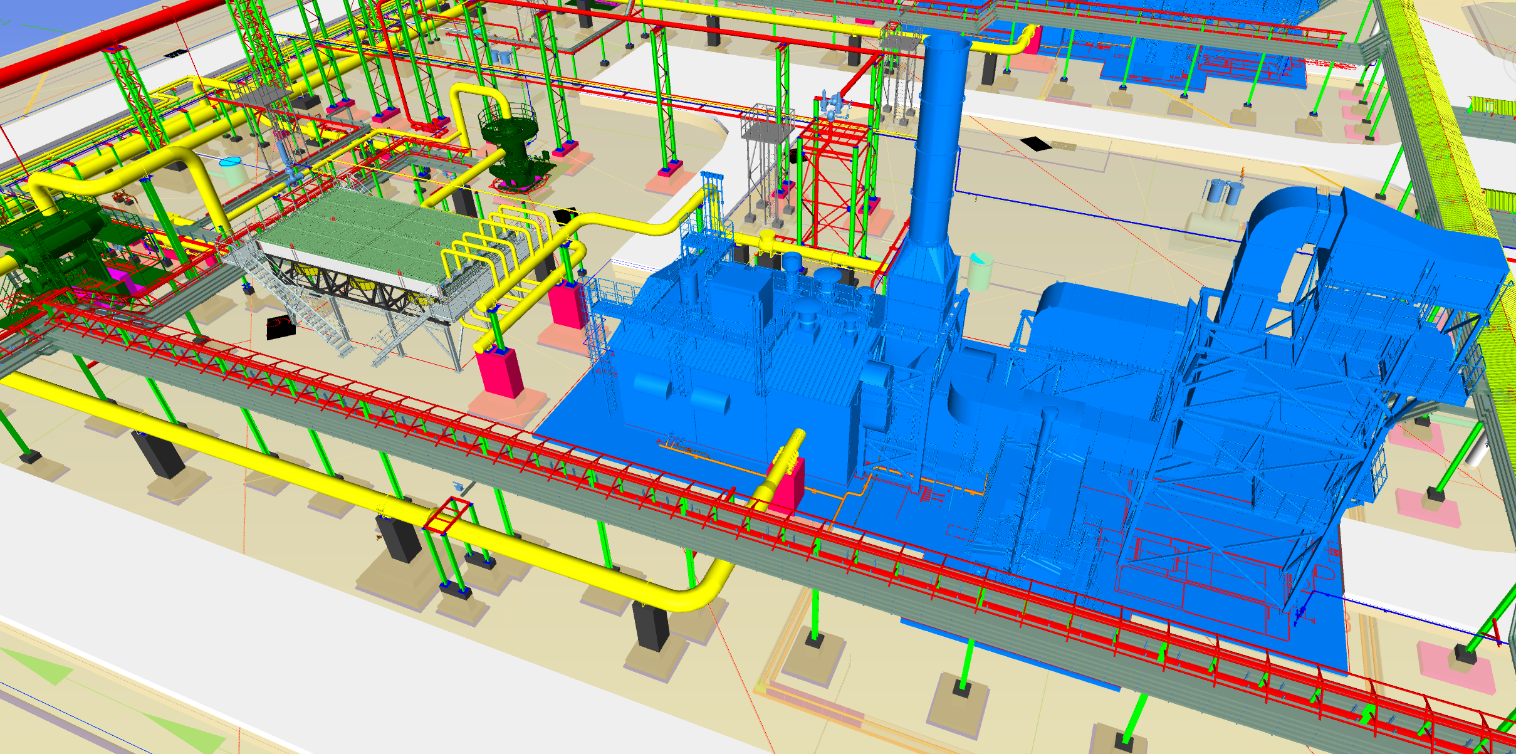

The project provides for construction of Booster Compressor Station with two compression lines, single gas compression stage and centrifugal single case compressor units PCL-504 with a unit rating of 8 MW. Configuration (2 duty + 0 standby) driven by АИ

Main process flow diagram provides for packaged Compressor station with all life support, control and protection systems as well as air contamination, vibration, fire extinguishing and fire detection, electrical and pneumatic supply detectors, including:

- Compressor station inlet separator unit С-001

- Reciprocating compressors GCU-100/GCU-200

- Inlet separator unit С-101/С-201

- Gas air cooler unit AC-101/AC-201

- Outlet separator unit С-102/С-202

BCS auxiliary systems:

- Gas treatment system for internal needs (fuel, flare header blowdown)

- Fuel and buffer gas treatment system (provided by GCU supplier)

- Oil supply system

- Air and nitrogen treatment system

- Liquid collection and transfer system

- Gas discharge to the flare (provided to the existing system)