PROJECT GOAL

Development of Mustakillikning 25 Yilligi field, with the construction of a gas processing plant and all the required infrastructure facilities in order to ensure the production, treatment and processing of high-sulfur natural gas in the amount of 5.0 billion cubic meters per year, supplied from the field development facilities, and receiving marketable products — sales gas for further transportation via the export gas pipeline and granulated and lumpy sulfur.

Nominal design capacity is 5.0 billion Nm³ per year (2 trains of GPP for processing 2.5 billion Nm³ per year each).

Production range of GPP commercial products:

- Sales gas — up to 4.4 billion cubic meters per year;

- Granulated sulfur — up to 460 thousand tons/year (clarification will be made by calculation), according to GOST

127.1-93 “Technical sulfur”

BOYSUN GPP SCOPE

|

Process |

Offsite systems |

Buildings and structures as part of GPP |

|

Unlicensed systems of: • Inlet Separation; • Gas dehydration, • Formation Water Treatment; Licensed systems: • Acid gas removal (under the Shell license); — Sulfinol M; — Sulfinol X. • Sulfur recovery and off-gas treating (under the Shell license). • Chemical oxidation of waste water (Shell license) |

• Fuel gas system; • Flare systems; • Plant and instrument air unit; • Nitrogen production and distribution unit; • Raw water treatment and distribution system; • Demineralized water treatment system; • Potable water treatment system; • Utility water supply system; • Fire protection water supply system; • Cooling water system; • System of steam supply and steam condensate re-treatment; • Heat supply system; • Gathering system and waste water treatment; • Electricity generation and distribution system; • Emergency power supply system; • Automated system of fire extinguishing, fire detection and gas contamination control; • CCTV for process facilities |

• Central control room (CCR); • Administrative and amenity building with a canteen; • Buildings of GPP transformer substations; • Remote Instrument Building (RIB); • Laboratory building; • Storage warehouses for chemicals, catalysts; • Maintenance shop; Entry Checkpoint and Technical Security Equipment Set (KITSO) |

SCOPE OF WORKS.

Detailed documentation development, in terms of

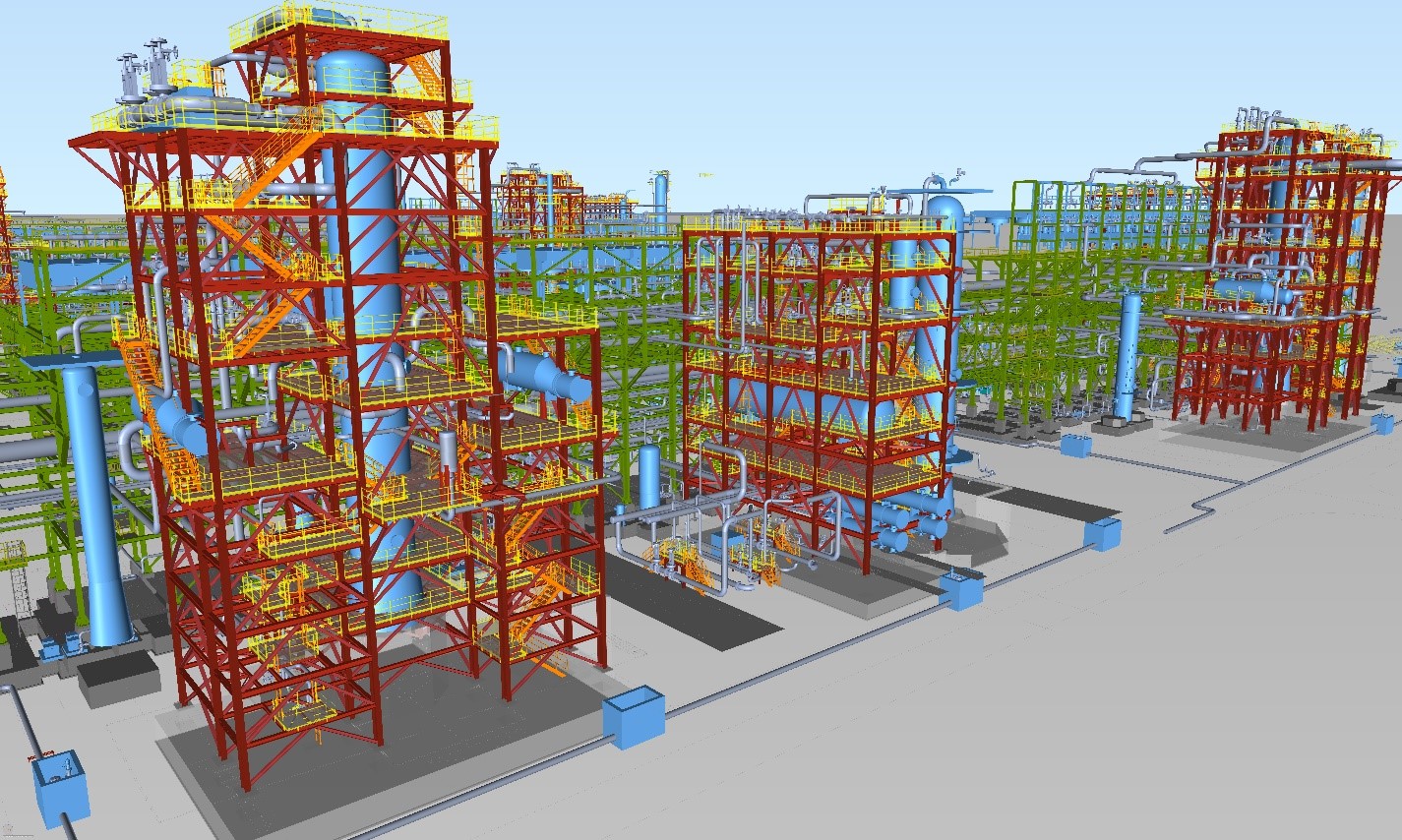

- Development of Project 3D model

- Project process and installation part

- Instrumentation part

- Electrical part (including power supply, power distribution, lighting, grounding and lightning protection)

- Part of water supply, sewerage and fire extinguishing

- Part of fire and gas detection, fire alarm

- Part of heating, ventilation and air conditioning

- Communication, alarm and video surveillance systems

- Plot plan and transportation part (including landscaping)

- Construction part (reinforced concrete structures, metal structures)

- Architectural part of buildings and structures

- Environmental Effects Statement, Environmental Impact Assessment (EIA) (if necessary)

- Industrial Safety Declaration (ISD)