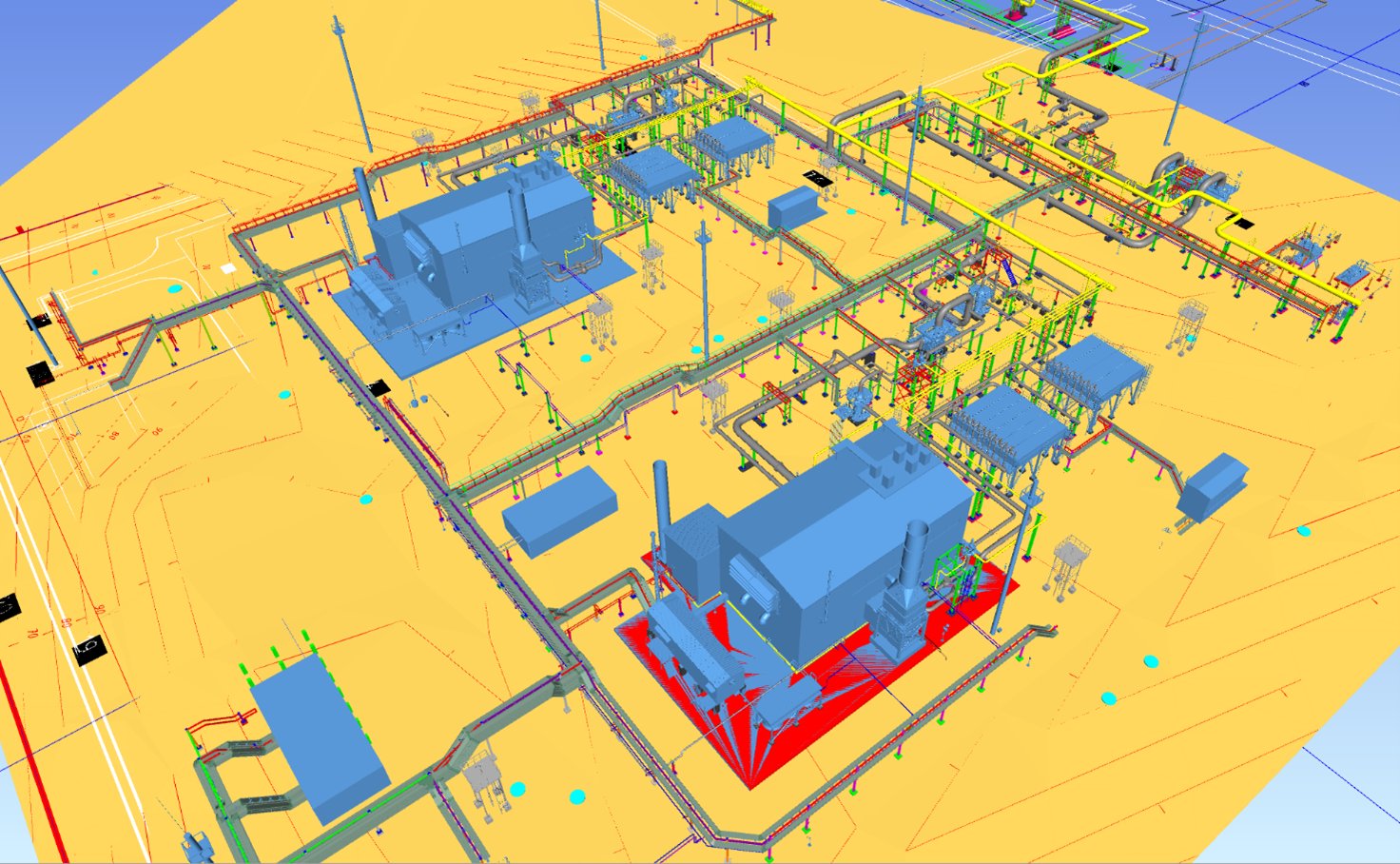

BCS is designed to maintain high sulfurous gas pressure at the inlet of existing BCS-1 of Dengizkul field under formation energy depletion conditions in order to ensure processing and further transportation of the gas.

High sulfurous gas is fed from wells to BCS inlet in the amount of

BCS technical data:

- Gas production rate, MSCM/d 6.50...3.68

- Inlet gas pressure, МРа (g) 1.47...0.37

- Discharge gas pressure, МРа (g) 5.4

- H2S content, % mol. 4.038

- Number of Gas compressor units, pcs. 2 (2+0)

- Unit capacity of Gas compressor unit, MW 16.0

Gas compressor units are arranged in individual shelters and designed basing on:

- Gas turbine drive NOVA LT16

- Reciprocating compressor 2BCL608

The following units and systems are included in BCS:

- Inlet and outlet valve assembly

- Compressor station inlet separator unit С-001

- Reciprocating compressors GCU-100/GCU-200

- Inlet separator unit С-101/С-201

- 1st stage gas air cooler unit AC-101/AC-201

- 1st stage separator unit С-102/С-202

- Gas air after cooler unit AC-102/AC-202

- Outlet separator unit С-103/С-203

BCS auxiliary systems:

- Gas treatment system for internal needs (fuel, buffer, flare header blowdown)

- Fuel and buffer gas treatment system (provided by GCU supplier)

- Oil supply system

- Air and nitrogen treatment system

- Liquid collection and transfer system (provided to the existing system)

- Gas discharge to the flare (provided to the existing system).

- Control room

- BCS PCS

- Transformer substation 6/0.4kV

- Operational and maintenance block

- Fire pump house

- Water treatment unit